High development speed thanks to rapid findings

Simulation

Resource-intensive trials and product tests can often only determine the consequences of a problem: Deformation, overheating, condensation…

Realistic simulation can provide valuable input both in the complex identification of possible faults and in the proposed solution to rectify them. As simulation means that fewer or no prototypes need to be built, development costs are reduced.

Simulations provide an overview of the entire system. While a load analysis on an assembly usually only examines a local point, after carrying out a simulation you have also analysed the neighbouring components and automatically look beyond the end of your nose.

We have a wide range of simulation programmes in-house, including for special applications. For example, CFD-Star CCM+, Ansys, LS-Dyna and OptiSLang

The following list gives you an overview of what we can do for you in the field of simulation:

- Static simulation, implicit structural mechanics

- Linear and non-linear calculations, strength analysis

- Plastic material behaviour

- Fibre-reinforced plastics with anisotropic material behaviour

- Mechanical and thermal loads

- Collision and contact problems

- Creep and settling behaviour

- Rotating systems, angular velocities and angular accelerations

- Design point studies, parameter optimisation

- Modal analyses

- Dynamic simulation, explicit structural mechanics

- Highly non-linear systems

- Acceleration and braking (drop test, impact/crash)

- Forming processes, anisotropic material behaviour

- Flow simulation, numerical fluid mechanics CFD

- Cooling analyses (oil, water, air)

- Bubble formation analysis

- Design optimisation for heat transfer

- Thermal management for electronics, motors, batteries…

- Multiphase analysis

- System simulation

- Design of complete systems in the simulation programme

- Electromechanical systems

- Fluidics with conveying

- Thermal management

- Tolerance analysis

- Two-dimensional and three-dimensional analysis of assemblies, taking into account shape and position tolerances

- Moving systems

- Loaded systems

- Troubleshooting for products on the market

- Merging of development and production data for a statistical analysis of the system

- Parameter studies to analyse important influencing factors

- Virtual verification

- Verification is now also recognised via simulations and thus saves costs for the construction, testing and analysis of prototypes or pilot series

- Please contact us if you are interested in this. We will be happy to advise you!

- Validation of the simulation results in our test laboratory

- Force measurements, tensile tests

- Customised test setups

- Determination of material parameters

Tools:

- Ansys Mechanical

- Ansys LS-DYNA

- Simcenter STAR-CCM

- Ansys optiSLang

- CETOL 6σ

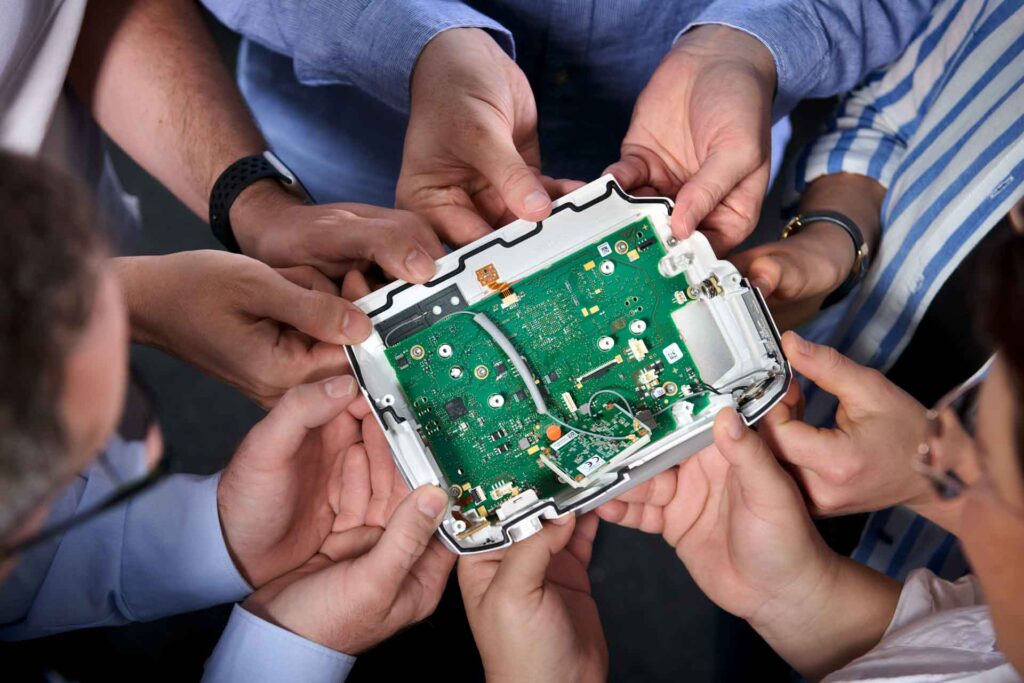

Project examples:

- Thermal management of a battery storage system

- Management of temperature and electromagnetism of an electric motor

- Optimisation of parameters of a test field strip in diabetes

- Crash analysis of an infusion pump

- Aeroacoustic analysis of a compact fan

- Tolerance optimisation for the safe manufacturability of a blood glucose meter