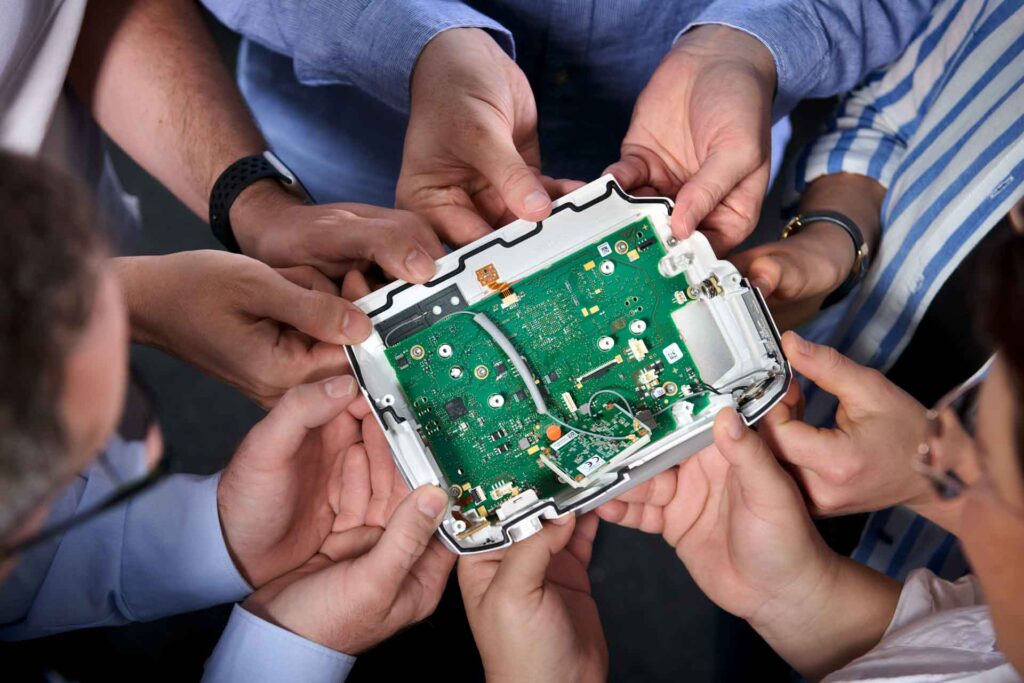

Safe products

Risk management

Risk… by definition, we are talking about negative events that occur with a certain probability. We do not want the success of your product to become a ‘game of dice’.

What we do not promise you: That we simply eliminate risks; it is partly out of our hands.

In risk management, we help you to minimise the risks

- as far as possible: Uncovering even distant cause-and-effect relationships is important and provides you with a solid information base for your decisions.

- reliably assess risks: A clear prioritisation of identified risks allows you transparency so that you can deploy your resources most effectively.

- address efficiently: Quick and focussed responses, or even better, proactivity rather than reaction will bring you quality results.

Knowing your risks now and taking countermeasures at an early stage will save you time and money over the course of the development and product life cycle. This is because risks that are addressed in advance will not lead to failure in the market.

For product developments in medical technology, we work in accordance with DIN EN ISO 14971. In addition, we carry out FMEAs and other quality methods and, if required, implement them in your company and train your employees to use these methods independently.

Project examples:

- High-voltage distributors in electromobility

- Risk assessment of the manufacturing process for spinal implants

- FMEA during development in infusion technology